It has been busy the last few months, and I have been neglecting this site. I'm back in Seattle right now on vacation and preparing to fly south. I just got back from firefighter training and team building with my fellow winterovers. Stay tuned for that excitement in my next blog post! With this very belated post I'll cover some of the things going on with the telescope since the last update. While I was back in Minnesota our goal was to assemble as much of the telescope as possible and test all the functionality as we could before taking it apart to be sent south. I was responsible for several of the systems on the telescope, and those came together fairly nicely. Hopefully they continue to work in the cold antarctic environment!

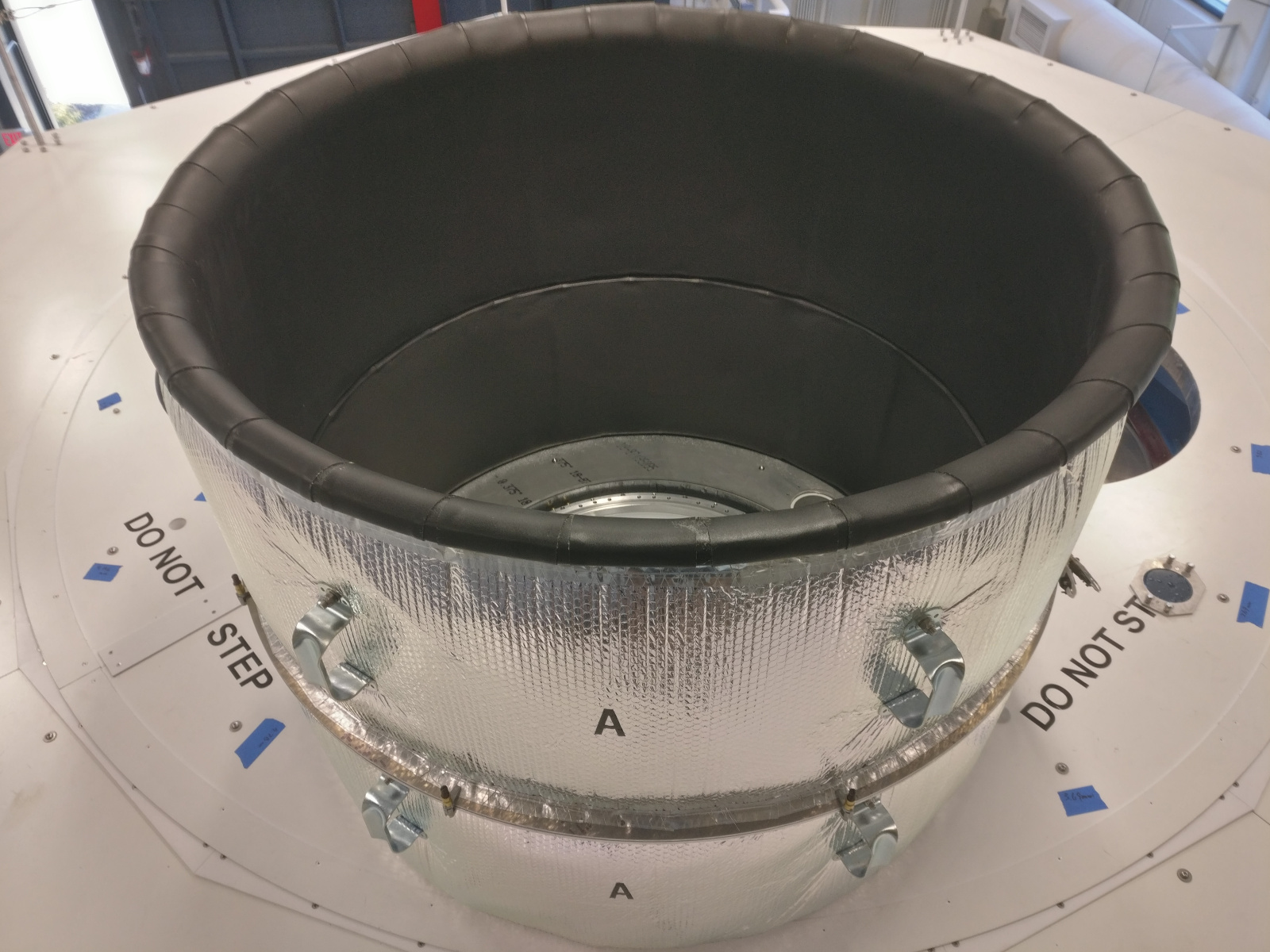

My first project that was assigned to me but only completed recently are the receiver forebaffles. These are essentially lens hoods for each of the four receivers. It works in very much the same way as a lens hood for a regular camera, just much bigger. It is outfitted with microwave absorbing material which helps reduce scattering of undesired off-axis light into our lenses for a clearer image of the observing target. Of course, because the forebaffle is basically a big aluminum can with an open top, snow will just pile up in there and ruin the performance of our telescope. To prevent this we wrapped the aluminum structure with electric heating cable and insulated the outer surface against the antarctic air. Because the humidity is so low and we don't have enough power to warm the forebaffle above freezing, this doesn't actually melt the snow but it does increase the rate at which the snow sublimates (converts directly from ice to water vapor in the air).

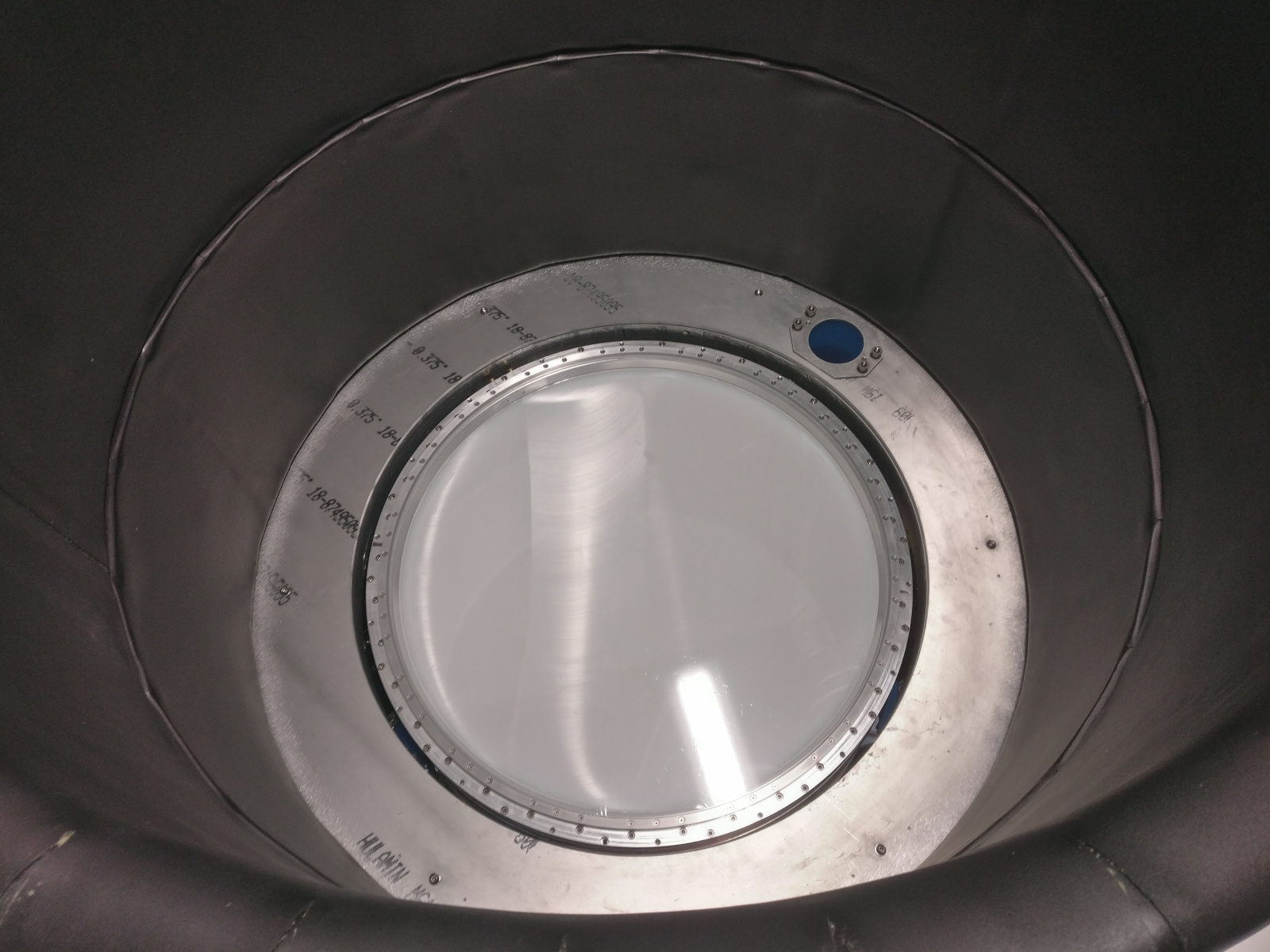

I also worked on a system that is used to keep the window of the telescope receivers clear of snow and ice. The windows are made from HDPE plastic, which is opaque optically but transparent in the microwave frequencies. The window is exposed to the cold antarctic air, and will accumulate snow and ice if we don't do something about it. The window is covered with a very thin membrane and the space between is pressurized with nitrogen. The membrane has a controlled leak rate so gas at room temperature is constantly flushing through the pressurized cavity, providing a small amount of heat to combat ice buildup.

A very interesting subsystem I was responsible for is the star camera equipment. These small optical cameras attach to the telescope mount and receivers. Every so often we will pause CMB observations and through the cameras pinpoint a variety of stars whose positions in the sky are known precisely. By centering each star in each camera and recording the mount position (azimuth, elevation, theta axis encoder positions) we can check for problems with or changes in the telescope mount. These deviations may be caused, for example, by settling of the observatory building into the ice or flexibility of the telescope mount. In the past the star cameras have been relatively small custom made optical telescopes. For BICEP Array, we are trying out a new system using an off-the-shelf camera lens attached to an hobby grade astrophotography camera. We must be able to resolve the position of a star to within about 1/1000th of a degree. Grantland, one of the grad students who works in the lab with me, was able to get the telescope tracking software to home in on a headlamp hanging from the crane hook which was a fun way of testing the cameras. Unfortunately we aren't able to test the system out with real stars until we get the telescope assembled at the south pole. That will be very cool when we have the opportunity.

There were also a lot of little details that required our attention before the telescope shipped. Getting the telescope mount properly insulated was a lot of work. Heavy insulation panels cover the top and bottom of the mount and required hundreds of match-drilled holes. At the very last minute we received our insulating 'boot' from the manufacturer, which is a large insulated fabric cover that wraps around the sides of the mount. The boot has metal frames to hold its shape and it collapses and expands accordion-style as the telescope tilts in elevation. We finished installing and testing this part with not a day to spare.

Disassembly immediately began after the boot was up and working. We broke the telescope down into pieces small enough to fit into an LC-130 cargo plane. It was a remarkably rapid process, which speaks to the consideration put into the design for the unique logistical requirements of getting a large telescope to one of the most remote, harsh places on Earth. Of course, we had it easy in a climate controlled room and an overhead gantry crane. It will be a different story putting it back together down south when summer temperatures are -20F and the wind is blowing.

The parts were placed on trucks and sent on their way to Port Hueneme, CA for their journey across the Pacific. The last of two trucks with our heavy equipment rolled out of the UMN high bay on September 27, leaving only smaller bits of sensitive equipment for us to pack up and ship via commercial air freight. The logistics involved with getting people and things to the south pole is impressive, and will be deserving of its own blog post sometime.

My last day of work at the University of Minnesota was October 11th. The next morning I packed up and started the long drive back home. I wanted every single day at home I could get, and finished the 1700 mile drive in two very long days.